Not known Incorrect Statements About Whole House Reverse Osmosis Water Filtration System

Table of ContentsThe Only Guide to Whole House Reverse Osmosis Water Filtration SystemThe Whole House Reverse Osmosis Water Filtration System StatementsAll about Whole House Reverse Osmosis Water Filtration SystemThe Of Whole House Reverse Osmosis Water Filtration System

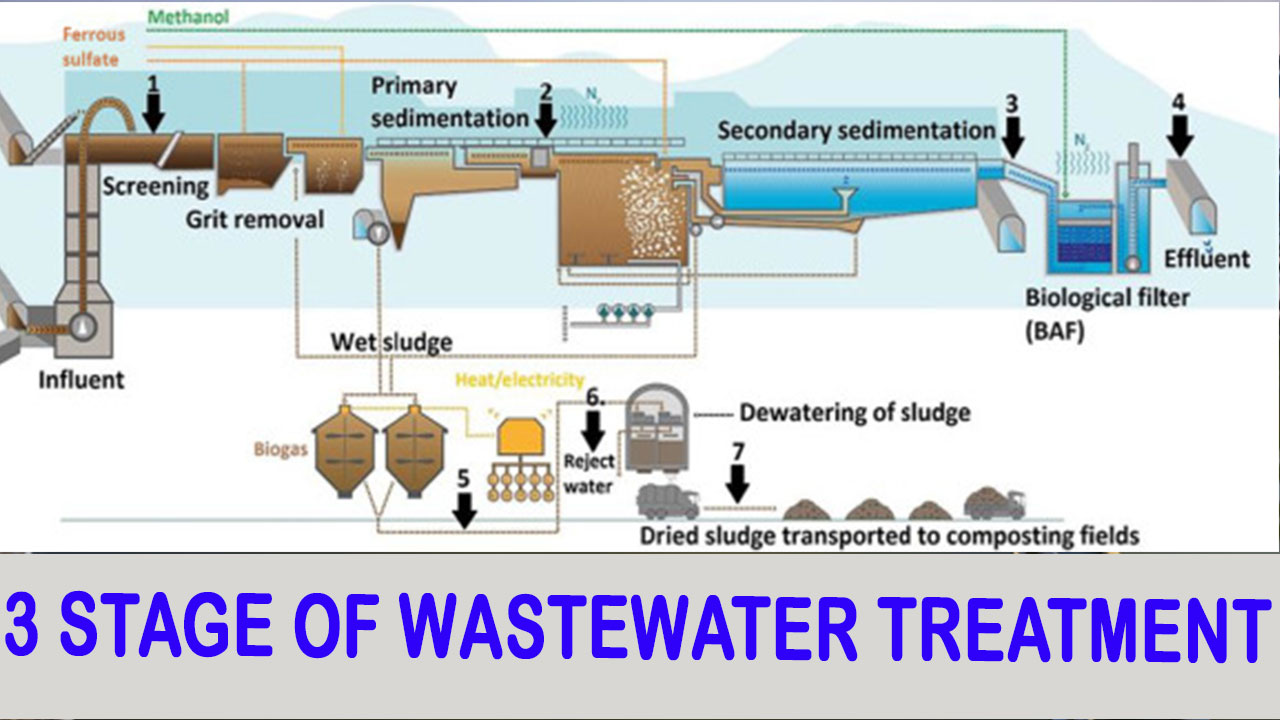

Phase Four Aeration Air is pumped into the oygenation tank/basin to encourage conversion of NH3 to NO3 and also offer oxygen for microorganisms to remain to proliferate and also grow. When converted to NO3, the microorganisms remove/strip oxygen molecules from the nitrate particles and also the nitrogen (N) is provided off as N2 (nitrogen gas).This starts in the aeration container. The primary function of the oygenation storage tank is to pump oxygen right into the tank to motivate the break down of any kind of organic material (as well as the development of the germs), along with make sure there is enough time for the organic material to be broken down.

This process is managed to offer the best problems for bacterial growth. Dissolved oxygen monitoring at this phase of the plant is essential. Ammonia as well as nitrate measurements are usual to gauge how efficient the bacteria are in transforming NH3 to N2.

Figure is a surrogate sign for the amount of organic material present and also is used to identify the effectiveness of natural material break down. There are a number of various other examinations used to guarantee optimum natural material failure (as well as figure decrease) such as measuring p, H, temperature level, Dissolved Oxygen (DO), Overall Suspended Solids (TSS), Hydraulic Retention Time (flow price), Solids Retention Time (amount of time the microorganisms remains in the aeration chamber) and also Mixed Liquor Suspended Solids.

Whole House Reverse Osmosis Water Filtration System - Questions

Stage 5 Additional Clarifier Dealt with wastewater is pumped into an additional clarifier to enable any staying natural debris to settle out of cured water circulation. As the influent exits the aeration procedure, it moves into an additional clarifier where, like the key clarifier, any kind of very small solids (or fines) sink to the base of the container.

Component of this triggered sludge is gone back to the oygenation storage tank to raise the bacterial concentration, aid in breeding, and also accelerate the break down of organic product. The extra is thrown out. The water that streams from the second clarifier has substantially decreased organic material and should be approaching expected effluent requirements.

With the enhanced concentration of bacteria as part of the oygenation phase, there is a demand to evaluate the outgoing effluent for germs existence or absence and also to decontaminate the water. whole house reverse osmosis water filtration system. This guarantees that more than defined focus of bacteria are not released into the atmosphere. Chlorination is the most typical and low-cost sort of disinfection yet ozone and UV sanitation are additionally boosting in appeal.

Americans are lucky to reside in a country with one of the most safe water products in the globe. According to the Epa (EPA), 286 million people get their drinking water from a neighborhood water supply. To make water secure for public consumption, it undertakes a series of treatments and also tests on its journey from resource to tap - whole house reverse osmosis water filtration system.

Things about Whole House Reverse Osmosis Water Filtration System

Health And Wellness Risks of Alcohol Consumption Contaminated Water Drinking water has the potential to be polluted at its resource as well as within the water circulation system. The EPA is responsible for regulating the top quality of the drinking water in the U.S. as well as sets the optimum allowable levels for concentrations of different contaminants.

Sedimentation The second stage takes area when the suspended matter as well as microorganisms settle at the end of a container. The longer the water rests uninterrupted, the a lot more solids will certainly yield to gravity and also be up to the container floor. Coagulation makes the sedimentation process a lot more effective because it makes the bits bigger and also heavier, triggering them to sink a lot more promptly.

This straightforward, affordable application is a necessary pre-treatment step before the filtration and sanitation phases. 3. Purification At this phase, the floc fragments have actually cleared up to the base of the water and also the clear water awaits further treatment. Filtering is required because of the little, dissolved fragments that special info are still existing in clear water, which consist of dirt, bloodsuckers, chemicals, viruses, and also microorganisms.

About Whole House Reverse Osmosis Water Filtration System

This is different than the type that can hurt the indoor air high quality around pool. The primary impact of the sanitation process is to oxidize and eliminate organic matter, which avoids the spread of parasites, infections, and also microorganisms that might stay in the alcohol consumption water. Disinfecting additionally serves to shield the water from bacteria it might be subjected to during distribution as it is piped to homes, colleges, businesses, and various other locations.

Plant Procedure The Buffalo Pound Water Treatment Plant is staffed 24-hour a day, 365 days a year with specialized and also extremely experienced water quality experts. With using advanced control systems as well as progressed instrumentation, the Plant and also our staff ensure a continual supply of top quality water to our clients, in amounts that fulfill their demands.

The dissolved oxygen must be eliminated utilizing the waterfall system. During waterfall de-gasification process, the water tips over a anonymous series of actions. This process launches the excess dissolved oxygen and prevents the development of oxygen bubbles in later treatment processes. Oxygen bubbles can connect to particles in the water that have actually developed a cosy precipitate called floc, causing these fragments to drift as opposed to sink.

If taste as well as smell in the water comes to be raised during cold weather, and also the granular triggered carbon (GAC) system, (Phase 6), is not in use, special-interest group is included in the Flocculation phase to aid in minimizing preference and odour. In this phase, aluminium sulphate (alum) is vigorously mixed with the water.